Magnus Larsson CEO MoRe: "RISE takes over and develops MoRe's offerings"

"The journey that MoRe Research and RISE began together in 2019 is now being developed further. Together, we will be even better equipped to develop innovative solutions that strengthen Swedish industry and contribute to a sustainable future", says Magnus Larsson CEO MoRe Research.

Important information about our website

We would like to inform our visitors that our current website www.more.se will be available until 31 March 2025. After this date, our offers and services will only be available on the RISE website www.ri.se.

MoRe Research AB to be integrated into RISE - For a stronger and more unified customer experience

In the autumn of 2024, MoRe Research AB Örnsköldsvik will be fully integrated with RISE Research Institutes of Sweden. As an important step in our long-term strategy, the MoRe Research brand will be phased out, creating a unified and powerful platform to better meet our customers' needs.

Toward Sustainable Viscose-to-Viscose Production - article in MDPI

Researcher Diana Reyes Forsberg together with Nadine Hollinger, Jenny Bengtsson, Tahani Kaldeus, The Loop Factory has published an article showing that the potential of using discarded viscose textiles to produce high quality viscose fibers is limited by the low molecular weight of the cellulose and its further reduction in the recycling process.

Regenerated fibers from textile waste and virgin wood pulp

The consumption of textiles worldwide is extensive and continues to grow with increasing population, urbanization, and economic growth. The textile industry encompasses the manufacturing of clothing, household textiles, technical textiles, and much more, making it one of the largest industrial sectors globally.

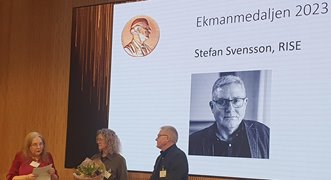

Stefan Svensson Ekman Medalist 2023

On January 30th, Stefan Svensson, from RISE, was awarded the Ekman Medal 2023 at the Ekman Days 2024 organized by SPCI, the Swedish Association of Pulp and Paper Engineers. Excerpt from the motivation: "Stefan has worked for many years at the research laboratory, always maintaining close contacts with the industry. His area of work has included process changes leading to improved economy, quality, environment, and operability."

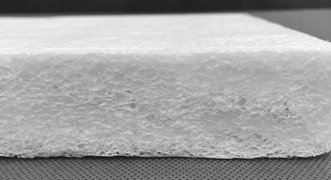

Testbed for sustainable foam materials

RISE Testbädd för Hållbara Skummaterial är inriktad på forskning och teknikutveckling kring lågdensitetsmaterial baserade på bioråvaror, restströmmar och återvunna material. Här har vi samlat olika kompetenser samt infrastruktur för uppskalning, förbehandling och analyser. Piloten ingår i Bioeconomy Arena.